The technical specification of a rolling shutter encompasses its materials, dimensions, weight, insulation properties, motor requirements, and operational mechanisms.

Basic Materials

The choice of materials for rolling shutters can significantly influence their durability, aesthetics, and functionality. While a variety of materials are available, some have emerged as popular choices due to their inherent properties and cost-effectiveness.

Commonly Used Materials for Shutters

- Aluminum: Lightweight and rust-resistant, aluminum shutters are known for their sturdiness and aesthetic appeal. They are highly resistant to corrosion, making them a good choice for areas with high humidity or saline atmospheres. On the cost spectrum, aluminum is relatively moderate, often priced between $20-$40 per square foot, depending on the finish and thickness.

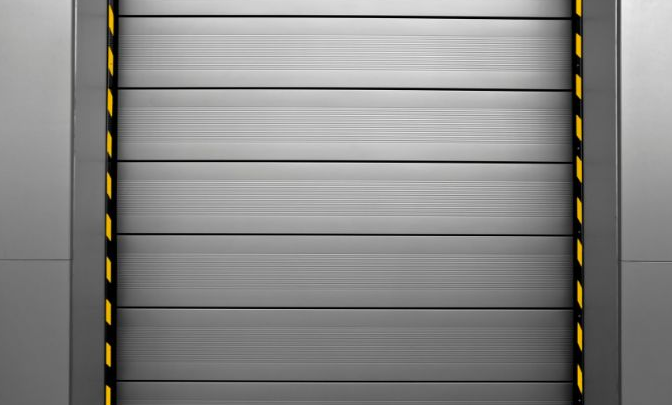

- Steel: Durable and robust, steel shutters are preferred for areas requiring high security. They might be susceptible to rust if not adequately treated, but their strength is unparalleled. Steel shutters typically range from $25-$50 per square foot.

- PVC: An economical option, PVC shutters are lightweight and easy to install. They are not as durable as metal counterparts but are resistant to rust and corrosion. PVC shutters can cost as low as $10-$25 per square foot.

- Wood: While not as common, wood shutters offer a unique aesthetic appeal. They require regular maintenance to prevent decay and are generally more expensive, with prices ranging from $50-$100 per square foot, depending on the type of wood.

Durability and Maintenance Considerations

The longevity of a rolling shutter is closely tied to its maintenance and the initial material choice:

- Regular Cleaning: Dust and debris can get trapped in the shutter’s grooves, causing wear and tear. Aluminum and steel shutters, in particular, benefit from periodic cleaning.

- Lubrication: Ensuring that the rolling mechanism is well-lubricated can prevent unnecessary strain on the material, especially important for metal shutters.

- Protection Against Corrosion: While materials like aluminum naturally resist corrosion, steel shutters may require protective coatings or treatments, especially in damp environments.

- Inspections: Periodic inspections can help in early identification of issues like cracks or deformities. It’s especially vital for wooden shutters which may suffer from rot or insect infestations.

Technical Specifications

The technical specifications of rolling shutters are paramount in determining their utility for a specific application. From size to safety, each specification contributes to the shutter’s efficiency, cost, and lifespan.

Dimensions and Standard Sizes

- Residential Shutters: Most commonly found in sizes ranging from 3 feet to 10 feet in width. The height typically falls between 7 feet to 8 feet. These dimensions cater to standard home garages or windows.

- Commercial Shutters: For storefronts or larger openings, widths can extend up to 20 feet or more, with heights of 12 feet or higher. Pricing can vary based on the size, but a general estimate is around $40-$70 per square foot for commercial-grade shutters.

- Customized Dimensions: For unique architectural requirements or designs, custom sizes can be manufactured. However, these tend to be pricier, often costing an additional 20-30% compared to standard sizes.

Weight and Load Bearing Capacity

- Material Influence: Steel shutters, given their durability, are heavier than aluminum or PVC alternatives. The weight of a standard residential steel shutter might range between 150-300 lbs.

- Support and Installation: Ensuring that the surrounding architecture can support the shutter’s weight is crucial. For heavier shutters, reinforcing the installation points or having a robust support mechanism is essential.

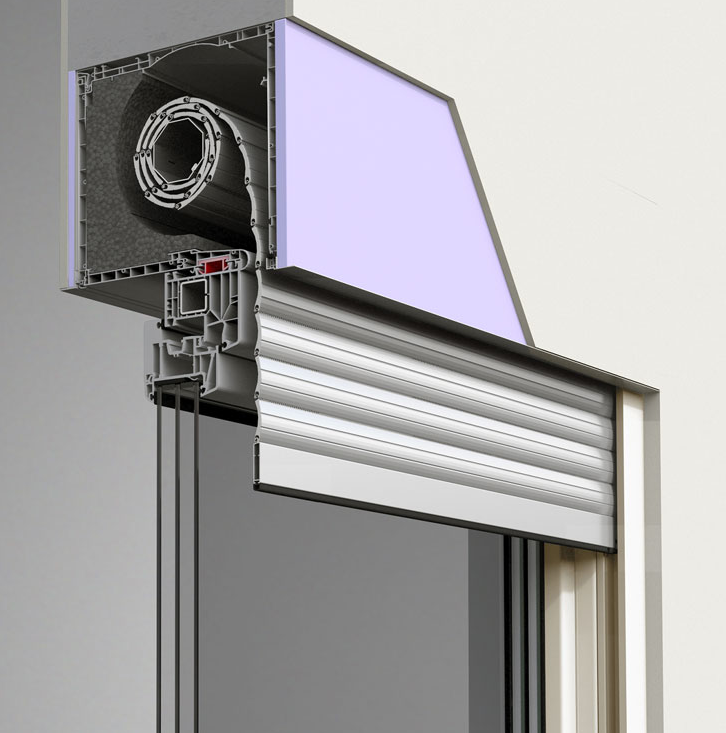

Insulation and Thermal Properties

- Insulated Panels: Many modern shutters come with insulated panels. This insulation, often made of polyurethane foam, provides excellent thermal resistance, reducing energy costs. Such shutters might cost an additional $10-$20 per square foot compared to non-insulated variants.

- R-Value: A measure of thermal resistance, higher R-values indicate better insulation. A good quality insulated rolling shutter can have an R-value ranging from 3 to 6.

Acoustic Insulation Properties

- Noise Reduction: Shutters, especially those with insulation, can significantly reduce noise pollution. This is particularly useful for properties near busy roads or industrial areas.

- Materials: Shutters made of dense materials like steel, combined with insulation, offer the best acoustic dampening.

Fire Resistance and Safety Features

- Fire-Rated Shutters: These are designed to prevent the spread of fire and can resist high temperatures for specified durations, such as 1 hour or 3 hours. Fire-rated shutters are more expensive, with prices starting from $100 per square foot.

- Safety Mechanisms: Many modern rolling shutters come equipped with safety features like auto-reverse (to prevent crushing objects) or manual override systems in case of power failures.

Mechanism and Operation

The mechanism and operation of rolling shutters greatly influence the user experience. The ease of operation, power consumption, and security are directly affected by the chosen operating system and additional features. Let’s delve into the intricacies of these systems.

Manual vs. Automated Systems

- Manual Systems: These are the traditional hand-operated shutters. They are cost-effective, with prices starting as low as $200-$400 for a standard residential size. A pulley, chain, or hand-crank is commonly used to roll them up or down.

- Automated Systems: Incorporating modern technology, automated shutters are motor-driven and can be controlled with the push of a button, remote controls, or even smart home systems. While offering considerable convenience, automated shutters tend to be more expensive, ranging from $500 to $2,000 based on the sophistication of the system and size of the shutter. Integration with smart home systems might be an additional cost.

Motor Specifications and Power Requirements

- Voltage: Most shutter motors operate on standard household voltage, typically 110V to 240V depending on the country.

- Power Consumption: The consumption varies based on the motor’s size and the shutter’s weight. A standard residential shutter might use a motor of 0.5 to 1 horsepower, consuming between 500W to 1,500W during operation.

- Battery Backup: Some advanced systems come with battery backup, ensuring operation during power outages. This feature might add $50-$150 to the total cost.

Locking Mechanisms and Security Features

- Manual Locks: Traditional shutters might have padlock-compatible latches or internal locking systems. These are generally included in the base cost of the shutter.

- Automated Locks: Modern automated systems can have integrated electromagnetic locks that engage when the shutter is fully closed. Such locks offer enhanced security against forced entries.

- Sensors and Alarms: Some advanced shutters come equipped with sensors that detect forced entries, triggering alarms. Incorporating these features can add anywhere from $50 to $300 to the shutter’s cost, depending on the sophistication and brand.

Installation and Mounting

Proper installation of rolling shutters not only ensures smooth operation but also enhances the longevity and performance of the shutter. Whether considering a DIY approach or seeking professional assistance, understanding the installation process and associated costs can aid in making informed decisions.

Pre-requisites for Installation

- Site Assessment: Before installing, assess the area for any obstructions or irregularities. Ensuring a flat and sturdy surface is crucial. This might involve leveling or reinforcing the mounting surface.

- Tools and Equipment: Depending on the type of shutter, specific tools might be necessary. This can include drills, levels, bolts, and ladders.

- Measurements: Precision is key. Accurate measurements of the opening ensure that the shutter fits perfectly. Remember, an improperly sized shutter can lead to operational challenges and reduced security.

- Electrical Considerations: For automated systems, proximity to a power source is essential. This might involve electrical wiring or setting up a dedicated circuit in some cases.

Professional Installation vs. DIY

- DIY Approach: A cost-effective choice for those handy with tools. While manual shutters might be relatively straightforward to install, automated systems can be more complex. The cost savings of a DIY approach can range from $100 to $500 or more.

- Professional Installation: Hiring professionals brings expertise and ensures that the shutter is installed correctly and safely. Depending on the complexity, professional installation can range from $200 to $1,000 or more. Many companies offer warranties or guarantees when opting for professional installation.

Integration with Existing Structures

- Existing Frames: If replacing an old shutter, it’s essential to check the compatibility of the new shutter with the existing frame. Some minor adjustments or reinforcements might be necessary.

- Aesthetic Considerations: The new shutter should complement the existing structure’s aesthetic. This might involve choosing a specific color, finish, or design that matches the property’s look.

- Safety and Building Codes: Especially relevant for commercial properties, it’s important to ensure that the installed shutter adheres to local building codes and safety standards.

Maintenance and Troubleshooting

Like all mechanical systems, rolling shutters require routine maintenance and occasionally face operational challenges. Timely checks and interventions can keep them functioning optimally, extending their lifespan and maintaining their efficiency.

Routine Checks and Maintenance

- Lubrication: Keeping the moving parts lubricated reduces wear and tear. Apply a suitable lubricant to the tracks, rollers, and other moving components at least once a year. The cost of a high-quality lubricant can range from $10 to $20.

- Cleaning: Dirt and debris can accumulate in the tracks and on the shutter surface. Regular cleaning prevents this buildup, ensuring smooth operation. Use a mild detergent solution and a soft brush for effective cleaning.

- Inspection: Periodically inspect the shutters for signs of damage, wear, or misalignment. This proactive approach can help identify issues before they escalate.

- Electrical Systems: For automated shutters, check the electrical components, including sensors, motors, and remote systems, for any anomalies. Surge protectors can be an excellent investment to protect the shutter’s electrical components, typically costing between $20 and $50.

Common Issues and Solutions

- Shutter Doesn’t Roll Smoothly: This can be due to debris in the track or a lack of lubrication. Cleaning and lubricating the tracks often resolve this issue.

- Motor Doesn’t Operate: It might be an electrical issue or a motor malfunction. Checking the power source and fuses can offer insights. If the problem persists, consulting a professional or the manufacturer’s troubleshooting guide is advisable.

- Noisy Operation: Excessive noise can be due to misalignment, wear, or lack of lubrication. Proper alignment and lubrication can remedy this.

Lifespan and Replacement

- Lifespan: With proper care and maintenance, a quality rolling shutter can last anywhere from 15 to 25 years. However, specific components, like motors or sensors in automated systems, might require replacement earlier.

- Replacement Parts: Rather than replacing the entire shutter, sometimes, only specific parts might need replacement. Common components like rollers, tracks, or remote controls can cost between $20 to $200, depending on the quality and brand.

- Complete Replacement: If the shutter faces significant damage or reaches the end of its operational life, a complete replacement is the best option. When considering replacement, evaluate the latest models and features, as advancements can offer better performance, security, and energy efficiency.