What type of garage door is sectional?

A sectional garage door is a type of garage door that is made up of multiple horizontal panels that are hinged together. When the door is opened, the panels move vertically along tracks, folding neatly into the overhead space. This design allows for efficient use of space and provides a convenient and secure option for garage access.

Introduction of Sectional Garage Door

Definition of Sectional Garage Door

A Sectional Garage Door is a type of garage door that opens and closes in separated individual panel sections, unlike the more common single panel garage doors that require more space for operation.

Detailed Specifications

- Height: Standard heights range from 6 to 8 feet, although custom sizes are also available.

- Width: Widths can range anywhere from 8 to 20 feet depending on the manufacturer and model.

- Material: Predominantly made from galvanized steel. However, aluminum, wood, and vinyl can also be used.

- Lifespan: Under proper care, these doors can last anywhere from 15 to 30 years.

Advantages of Sectional Garage Doors

Sectional Garage Doors offer several key benefits over traditional swing-out doors.

Space Efficiency

Sectional garage doors operate vertically, which means they do not require any space outside of the garage to open or close. This provides a major advantage for homes with a short driveway or those located on busy streets.

High Durability

Constructed from several horizontal panels, sectional doors are more resistant to damage. Even if one panel gets damaged, it can be replaced without needing to replace the entire door. This contributes to their overall lifespan, which can be as long as 30 years with proper care and maintenance.

Enhanced Security

Sectional garage doors are typically more secure than other types of garage doors due to their construction and operating mechanism. Each section of the door is connected to the door track, which provides added strength and security.

Cost-Effectiveness

While the upfront cost of a sectional garage door might be higher than single panel doors, in the long run, they can prove to be more cost-effective. They typically require less maintenance and have a longer lifespan.

Here is a summary of the key points:

| Factor | Sectional Garage Door |

|---|---|

| Cost | Higher upfront cost but lower maintenance costs |

| Lifespan | 15 – 30 years |

| Space Efficiency | Very high |

| Durability | High |

| Security | Enhanced |

Construction and Design Features

Panel Configuration and Materials

Panel configuration and materials determine the functionality, aesthetics, and longevity of your garage door.

Wood Garage Doors

Wood garage doors add a luxurious, vintage appeal to your property. They’re typically made of high-quality cedar, mahogany, or redwood. The price range for a wood garage door can vary significantly depending on size and type of wood, with prices ranging from $1,200 to $4,000 for standard sizes (e.g., 9 feet wide by 7 feet tall). One downside is the maintenance; wood doors require regular repainting or staining to maintain their appearance and prevent rot.

Steel Garage Doors

Steel garage doors are a popular choice due to their durability and relatively lower cost, starting around $750 for a standard size. These doors can resist the elements better than wood but may be prone to dents. Steel doors often come with a layer of polyurethane or polystyrene insulation, improving the energy efficiency of your garage.

Aluminum Garage Doors

Aluminum garage doors offer the same benefits as steel, but are lighter and less prone to rust. Prices are similar to steel, with an average cost around $800 to $1,200 for a standard size door. The lightweight nature of aluminum can make it more susceptible to damage, though.

Composite Garage Doors

Composite garage doors use a steel core and a faux wood exterior to offer the benefits of both. These doors require less maintenance than wood and are more resistant to dents than steel. Prices for composite doors start around $1,200 for standard sizes.

Track System and Hardware Components

A garage door’s track system and hardware components play crucial roles in its operation and longevity.

Standard Lift Track Systems

This is the most common track system for residential garage doors, designed for a standard 8 feet ceiling height. These cost around $150 to $250 depending on the quality and brand.

Vertical Lift Track Systems

These are used in commercial settings where the door needs to lift straight up. Vertical lift systems are more expensive than standard systems, typically costing $200 to $350.

High Lift Track Systems

High lift systems combine the features of standard and vertical lift systems. They’re most often used in residential settings with high ceilings. These systems generally cost $350 to $500.

Rollers

Garage door rollers are the small wheels that run along the track of the door. They come in three main types: plastic, steel, and nylon. Nylon rollers are the quietest and longest lasting, with a lifespan of around 12-15 years. They’re also the most expensive, costing about $15 per roller.

Insulation Options for Sectional Garage Doors

Insulation can help keep your garage temperature regulated and your energy costs down.

Polystyrene Insulation

Polystyrene is a cheaper insulation option, adding about $50 to $100 to the price of a garage door. It provides a moderate level of insulation, with an R-value (thermal resistance) typically between R-5 to R-8.

Polyurethane Insulation

Polyurethane insulation offers the highest level of thermal efficiency, with R-values up to R-18. This material is more expensive, typically adding $100 to $200 to the price of a garage door.

Window and Decorative Element Variations

Garage door windows and decorative elements add aesthetic appeal and natural light.

Window Options

Garage door windows can come in a variety of styles, shapes, and materials. Clear glass, frosted glass, tinted glass, and even acrylic or polycarbonate options are available. Depending on the style and material, windows can add $100 to $500 to the price of a garage door.

Decorative Elements

From hardware additions like handles and hinges to design elements like patterns and paneling, there are many ways to enhance the aesthetic of your garage door. Prices for decorative elements can vary significantly, from $20 for simple accents to $200 for high-end, custom elements.

Operation Mechanisms

Garage doors have several different types of operation mechanisms. Two of the most common are manual and automatic.

Manual Sectional Garage Doors

Manual sectional garage doors are the simplest type of garage door and generally the most cost-effective. Prices start from as low as $300 for standard sizes. They operate using a torsion spring system, which counterbalances the weight of the door to make it easy to lift by hand. Maintenance tends to be straightforward, usually requiring only regular lubrication of the moving parts.

However, the downside is the physical effort required to open and close the door. This can be inconvenient in bad weather or if you frequently enter and exit your garage.

Automatic Sectional Garage Doors

Automatic doors are also typically safer as they feature an auto-reverse function that prevents the door from closing on objects or people in its path.

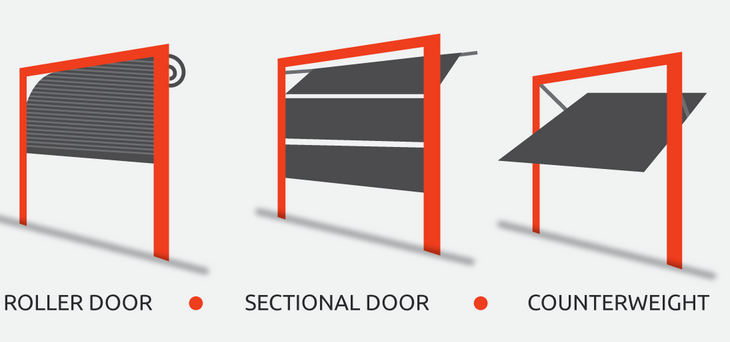

Comparison with Other Garage Door Types

There are a few other types of garage doors, and it’s worth comparing their features and costs to those of sectional garage doors.

Roll-Up Garage Doors

These doors are robust and ideal for commercial settings or homes in hurricane-prone areas. However, they are generally more expensive, with prices starting around $750 for residential models and up to $2,500 for commercial grade doors.

Swing Out Garage Doors

Also known as carriage doors, swing-out doors open outwards from the center. They can be a charming addition to a home, especially for those seeking a traditional or country aesthetic. Prices for swing-out doors start around $1,500. However, they require more clearance to open and close compared to sectional or roll-up doors, making them unsuitable for compact driveways.

Sliding Garage Doors

Sliding garage doors move horizontally along a track to open and close. They can be made from various materials, including wood, steel, and aluminum. The cost for sliding doors can range from $600 to $1,300 depending on the size and material. Sliding doors require enough wall space on one or both sides of the opening to accommodate the door when it’s open, which may limit their applicability for some homeowners.

Cost Factors and Budget Considerations

Initial Investment vs. Long-Term Savings

Purchasing a garage door is an investment. While there’s an upfront cost, a quality garage door can provide long-term savings in various ways.

Upfront Costs

The upfront costs of a garage door include the price of the door itself, which can range from $300 for a basic manual model to over $4,000 for a high-end automatic model. Additionally, professional installation typically costs between $200 and $500, depending on your location and the complexity of the install.

Energy Savings

Garage doors with proper insulation can lead to significant energy savings over time. An insulated door helps maintain a stable temperature in the garage, reducing the load on your home’s heating and cooling system. A polyurethane-insulated door, for instance, can add about $100-$200 to the upfront cost of the door, but the savings in energy costs can more than offset this additional expense over the door’s lifetime, especially in regions with extreme climates.

Maintenance Costs

Higher quality doors often come with a higher price tag, but they can also save you money in the long run by requiring less maintenance and repairs. For example, a steel or composite door might cost $200-$400 more than a basic wooden door, but wood requires regular repainting or refinishing that can add up to $50-$100 per year.

Factors Affecting Sectional Garage Door Prices

Several factors can influence the price of a sectional garage door, including:

Material

The material of the door is a significant factor. Wood, though attractive, is usually the most expensive material. Steel and aluminum are more affordable, with composite falling somewhere in between.

Insulation

The level of insulation you choose will affect the cost. Higher R-value insulation provides better energy efficiency but is more expensive.

Size

The size of the garage door will directly impact the cost. Larger doors require more material and therefore cost more. A standard single car garage door is about 8-9 feet wide and 7-8 feet tall, while a double car garage door is typically 16 feet wide.

Customization

Custom features like windows, decorative elements, and custom colors or finishes can add to the cost. For instance, adding windows can increase the price by $100 to $500.

Automation

Choosing an automatic garage door will add the cost of the garage door opener, which ranges from $150 to $300.

Installation

Professional installation costs vary depending on your location and the complexity of the job, but typically range from $200 to $500. Installation of an automatic door might be more expensive due to the additional labor involved in setting up the door opener.

Safety Measures for Manual Operation

Operating a manual garage door requires careful attention to safety. Here are a few key safety measures:

Proper Maintenance

Regular maintenance is crucial. This includes lubricating moving parts and regularly checking the door’s balance. A well-maintained door is less likely to stick or drop unexpectedly, which could cause injury. The cost of maintenance is relatively low, with lubricants costing around $10 per bottle.

Torsion Spring Safety

The torsion spring system in a manual door should always be in good condition. A failing spring can cause the door to fall rapidly, which can be extremely dangerous. Replacement springs typically cost around $50 to $100, and it’s recommended to replace them every 5-7 years.

Safety Cables

Safety cables can be installed to prevent a broken spring from flying loose and causing injury or damage. These cables usually cost less than $10 and provide an added level of safety.

Automated Systems and Safety Protocols

Automated garage doors come with built-in safety features that can further enhance the security of your property and protect users from injury.

Auto-Reverse Mechanism

It uses sensors to detect if an object or person is in the path of the door, and if detected, the door will automatically reverse direction. The cost of sensors ranges from $50 to $100.

Manual Release

In case of power outages or malfunctions, automatic garage doors have a manual release cord. This allows you to manually open or close the door in emergencies. Always check this feature during your regular maintenance.

Battery Backup

Some garage door openers offer battery backup systems. In case of a power outage, the backup kicks in, allowing the door to function normally. These systems add approximately $50 to $100 to the cost of a door opener.

Security Enhancements in Sectional Garage Doors

Security is a key consideration when choosing a garage door.

Locking Mechanisms

Most garage doors have integrated locking mechanisms. Manual doors often use a key, while automatic doors are typically locked and unlocked via the opener system. Advanced locking systems can be installed at an additional cost, usually between $100 to $300.

Smart Technology

Modern garage door openers often include smart technology features, such as Wi-Fi connectivity, allowing you to monitor and control your garage door from anywhere using a smartphone app. These smart garage door openers typically cost between $200 and $400.

Tamper-Resistant Brackets

Garage doors often use tamper-resistant brackets that prevent criminals from manually releasing the door from outside.