Which type of rolling shutter is best?

The best type of rolling shutter largely depends on individual needs. If speed and durability are a priority, high-speed roller shutters are excellent. For noise reduction and insulation, PVC or aluminum shutters are ideal. In a tight budget scenario, electronic rolling shutters, due to their lower cost, can be a great choice.

Introduction of Rolling Shutter

Definition of a Rolling Shutter

A Rolling Shutter is a method of image capture in which a still picture (or each frame of a video) is recorded not from a simultaneous snapshot of the entire scene but rather by scanning across the scene rapidly, either vertically or horizontally. Essentially, not all parts of the image of the scene are recorded at exactly the same instant.

These shutters are primarily used in digital cameras, including DSLR cameras, smartphone cameras, and high-speed cameras. The size of these shutters varies, but they typically range from 35mm to 50mm for most consumer digital cameras. The lifespan of a typical rolling shutter can be up to 5 years, given proper maintenance and usage.

The cost of a rolling shutter can vary widely, depending on the size and quality. A standard 35mm rolling shutter for a DSLR camera, for instance, might cost around $300, while a higher-end model might cost upwards of $1,000.

Importance of Choosing the Right Rolling Shutter

Choosing the right rolling shutter is crucial for several reasons. The primary advantage is the quality of the images or videos. A high-quality rolling shutter can provide sharper, clearer images and smoother videos, particularly in situations where there’s a lot of movement or action.

Another benefit is longevity and durability. Higher-quality rolling shutters are generally more robust and durable, which means they’re less likely to fail or need replacement.

However, it’s essential to weigh these benefits against the cost. More expensive shutters usually offer superior performance and longevity, but they may not be necessary for all users. For instance, a casual photographer may not require the same level of performance as a professional photographer, and so a lower-cost rolling shutter may be sufficient.

Finally, the size of the rolling shutter can also be a significant factor. Larger shutters tend to offer better image quality, but they can also be more expensive and may require more powerful cameras.

High-Speed Roller Shutter – One of the Best Roller Shutter

Features and Advantages of High-Speed Roller Shutters

High-speed roller shutters, as the name suggests, are designed for fast operation. They typically operate at a speed of up to 1.5 meters per second, significantly faster than regular roller shutters. This increased speed comes with several advantages:

- Efficiency: The high speed ensures quick opening and closing, minimizing energy loss and keeping heating and cooling costs down.

- Durability: High-speed roller shutters are usually constructed from high-quality materials like hardened steel or high-grade aluminum, enhancing their durability and lifespan. Depending on the quality and maintenance, the lifespan of these shutters can be up to 10 years or more.

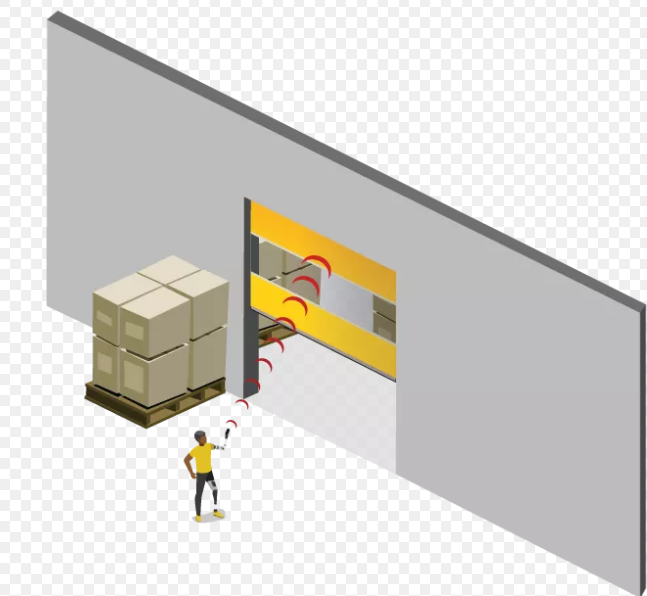

- Safety: Many high-speed roller shutters come with integrated safety features such as sensors that prevent the shutter from closing if there’s an obstruction.

- Cost-Effective: Although the initial cost can be higher – a typical high-speed roller shutter may cost around $1,500 to $3,000 – the improved energy efficiency and longer lifespan often make them more cost-effective over time.

Applications of High-Speed Roller Shutters

High-speed roller shutters are particularly beneficial in certain environments and applications:

- Industrial settings: In factories and warehouses, the fast operation can help to maintain a constant temperature and prevent dust or contaminants from entering.

- Commercial premises: In shops and retail environments, they can provide fast and effective security while also being visually appealing.

- Garages: They can provide quick and easy access while also providing a high level of security.

Performance Considerations for High-Speed Roller Shutters

When selecting a high-speed roller shutter, it’s important to consider the following performance factors:

- Size: The size of the shutter will impact the cost, speed of operation, and power requirements. Larger shutters may require more powerful motors, which can increase the cost.

- Material: The material can affect the durability, maintenance requirements, and appearance of the shutter. Hardened steel shutters are typically more durable but may require more maintenance than aluminum shutters.

- Speed: While high-speed shutters offer clear advantages, it’s important to consider whether the speed is necessary for your particular application. In some cases, a slower, more affordable shutter may be sufficient.

- Installation and Maintenance Costs: Apart from the initial cost of the shutter, it’s also important to consider installation costs and ongoing maintenance costs.

Understanding Rolling Shutter Mechanisms

Overview of Rolling Shutter Technology

Rolling shutter technology is an image capturing technique used in digital cameras. Unlike global shutters, which capture the entire image simultaneously, rolling shutters capture the image by scanning across the scene either horizontally or vertically. The exact speed of this scan can vary, but it’s typically extremely fast, often completed in just a few milliseconds.

This scanning process can create some unique effects. For instance, if the subject of the image or the camera itself is moving rapidly during the scan, it can result in a type of distortion known as “rolling shutter effect” or “jello effect”. This effect can be either a benefit or a drawback, depending on the desired outcome of the image or video.

In terms of cost, rolling shutters are typically less expensive than global shutters. They also tend to be smaller and consume less power, which can make them more suitable for certain types of cameras, especially those used in smartphones or other small, portable devices.

Different Types of Rolling Shutter Mechanisms

There are two main types of rolling shutters – mechanical and electronic:

- Mechanical Rolling Shutter: These shutters use a physical mechanism, typically a rotating disc or blade with an aperture, to expose the sensor to light for a brief period. The shutter then moves, or “rolls,” across the sensor to expose the next section.

- Electronic Rolling Shutter: In these shutters, the exposure and readout of the sensor are controlled electronically. The image is captured row by row, starting from the top and moving to the bottom.

Comparison of Mechanical vs. Electronic Rolling Shutters

| Feature | Mechanical Shutter | Electronic Shutter |

|---|---|---|

| Cost | Typically more expensive due to the complexity of the mechanical components. | Less expensive as they use simpler electronic components. |

| Speed | The speed can vary, but it’s generally slower than electronic shutters. | They can be extremely fast, often completing the scan in just a few milliseconds. |

| Size and Power Consumption | Tend to be larger and consume more power due to the mechanical components. | Smaller and less power-hungry, making them suitable for portable devices. |

| Durability | Can wear out over time due to the moving mechanical parts. | Tend to be more durable as they have fewer moving parts. |

| Image Distortion | Less prone to rolling shutter effect. | More prone to rolling shutter effect due to the high-speed scanning. |

Noise Reduction and Insulation with Rolling Shutters

How Rolling Shutters Contribute to Noise Reduction

Rolling shutters can play a significant role in noise reduction in both residential and commercial environments. When closed, they form a solid barrier between the interior of a building and the outside environment, helping to block out noise effectively. Depending on the material and quality of the shutter, noise reduction rates can vary, but a high-quality shutter can reduce outside noise by up to 50%.

This noise reduction is particularly beneficial in noisy urban areas, near busy roads, or in buildings with a lot of external noise. In such cases, installing a rolling shutter can lead to a significant improvement in the acoustic environment, leading to better comfort and productivity.

While the cost of noise-reducing rolling shutters can vary depending on factors like size, material, and quality, a typical price range can be between $200 to $600 per square meter.

Thermal Insulation Properties of Rolling Shutters

Besides noise reduction, rolling shutters also provide excellent thermal insulation. They can help to keep heat in during the winter and keep it out during the summer, contributing to energy efficiency and reducing heating and cooling costs. A quality rolling shutter can reduce heat loss by up to 10%.

The insulation property of a rolling shutter is determined by the material it’s made from and its design. Shutters made from materials with good insulation properties, such as PVC or aluminum filled with insulating foam, tend to offer better thermal insulation.

The cost of such thermally-insulating shutters can vary widely, depending on the size, material, and specific insulating technology used. But on average, one can expect to pay between $300 to $700 per square meter for a high-quality insulating rolling shutter.